Decontamination Modeling

For Plastics Recycling

Our CONTAINER SCIENCE® Decontamination Modeling service helps recyclers, brand owners, and equipment manufacturers evaluate and improve their recycling and decontamination processes.

Introduced in 2002, the CONTAINER SCIENCE® Decontamination Model is a proprietary computational tool developed and offered by CONTAINER SCIENCE® as part of our client consulting services. The Decontamination Model systematically analyzes and reports levels of contaminants during each stage of a plastics recycling process.

Verified by the FDA

CONTAINER SCIENCE® Decontamination Modeling has been verified by the FDA as a replacement for traditional surrogate contaminant testing. Our Decontamination Modeling service is used and trusted by recyclers, manufacturers and major brand owners.

Provides an understanding of contaminant levels

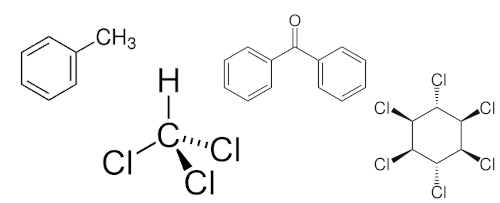

The CONTAINER SCIENCE® Decontamination Model includes analysis of acetaldehyde, toluene, limonene, H2O, CO2, ethyl butyrate, O2, chloroform, citral, linalool, ethylene glycol, tetracosane, lindane, benzophenone, and benzaldehyde. Other permeants can be added on request.

A typical modeling results package will evaluate toluene, chloroform, lindane and benzophenone to fulfill the FDA’s testing guidelines for volatile polar, volatile non-polar, non-volatile polar, and non-volatile non-polar surrogates.

The Model uses the beginning and final levels of each contaminant as specified by the FDA.

Polymers in the Model include PET, polyethylene, and polypropylene.

Accurate, consistent and economically superior to physical testing

CONTAINER SCIENCE® Decontamination Modeling provides a unique approach to determining the suitability of recycled plastic for food contact applications. While other approaches employ costly, time-consuming, and potentially flawed physical surrogate testing, the Decontamination Model is based upon actual measured diffusion and partition coefficients for the permeants at SSP temperatures.

The Decontamination Model takes into account polymer crystallinity, pellet/flake geometry and dimensions, and process temperatures. Results are accurate and reproducible, eliminating inconsistencies inherent in physical testing.

The Decontamination Model has been validated through extensive comparison to data generated from real-life scenarios since its introduction in 2002.

With our Decontamination Modeling service, clients can quickly identify processes needing improvement without the long wait times of physical testing.

Analyze processes and conditions

The Decontamination Model is a powerful tool for evaluating the decontamination effectiveness of current recycling equipment and assessing the viability of alternative equipment or process conditions.

With our CONTAINER SCIENCE® Decontamination Modeling services,

Brand Owners can:

- Evaluate products from current or potential suppliers, without the need for physical testing—saving time and money

- Evaluate processes after an audit

- Determine what level of approval suppliers have reached with their decontamination process

- Be prepared for changes in FDA guidelines or regulatory status

- Get a head start on the approval process

- Be prepared for audits by brand owners

- Save money and time by replacing the need for physical testing

- Evaluate different mechanical recycling systems when purchasing or upgrading

- Know what levels of decontamination their equipment is capable of providing

- Share decontamination results in Model summary reports with potential buyers

- Advise clients on the best ways to run their systems

- Evaluate efficacy of their machinery without costly and inconsistent physical testing

- Test the efficacy of a new equipment design before beginning production

Tailored to meet client requirements

The CONTAINER SCIENCE® Decontamination Modeling service is available on either a one-time basis or retainer basis. When you use our service, we will work with you to ensure your processes meet your requirements.

With each decontamination calculation we run for you, you will receive: 1) a comprehensive, easy-to-read summary report showing the final contaminant results after each step of your process; 2) the raw data in spreadsheet format, showing the concentration of each contaminant vs. time for each process step; 3) graphs of the contaminant levels over the course of each step.

Let us help you meet your decontamination objectives. Contact us today for more information.